Intuitive, fast and accurate

Ultimate Solution for Field Balancing

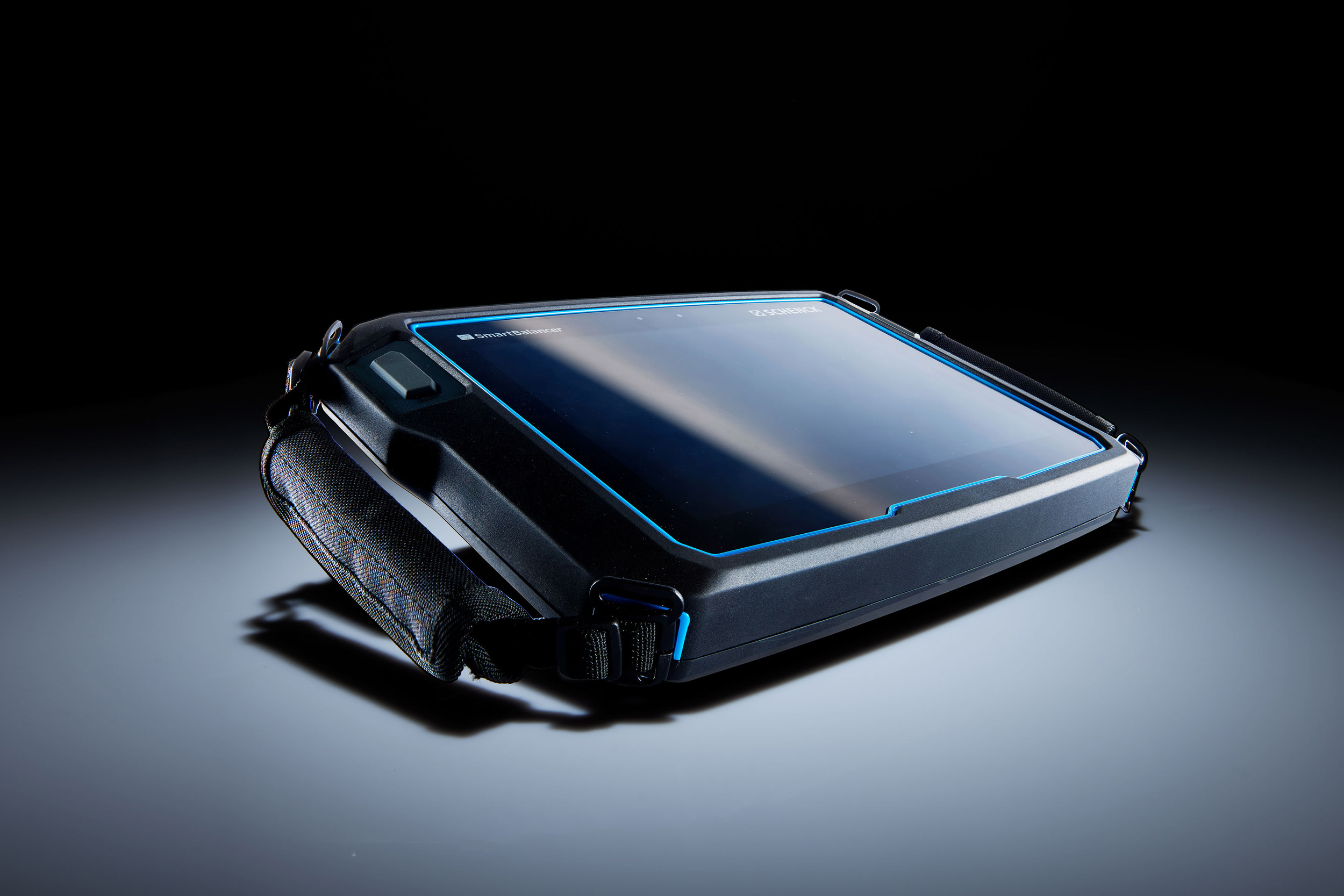

Studies substantiate: Over 50 % of faults or failures in machines and systems can be traced directly or indirectly to unbalances in rotors. Fortunately, with the innovative SmartBalancing Mode of SmartBalancer 4, the user can effortlessly detect and fix the unbalance in their machines and systems. Thanks to its exceptional functionality and user-friendly interface, this portable device stands as the ultimate solution for field service, maintenance, technicians.

Avoid unbalances in your operations

New Rotors may initially be balanced before their first use, but their balance can often be disrupted due to various factors such as installation, wear, and operational influences. These unbalances can result in mechanical vibrations during use, which can cause premature wear and tear of bearings, fatigue, force fractures, or shaft deformations. Fortunately, our SmartBalancer 4 is the ultimate solution to this problem. It allows for quick, cost-effective, and highly accurate balancing of rotors in their installed condition, without requiring machine dismantling. And this can be accomplished with up to six sensors simultaneously, operating at rotational speeds ranging from 120 to 80,000 rpm. In addition, the SmartBalancer 4 also comes with comprehensive diagnostic capabilities to keep you informed about the vibration condition of your machines, ensuring that your business operates smoothly and without interruptions, providing the best prospect for a smooth and trouble-free outcome.

The advantages at a glance

A complete package offering tremendous value for money

Up to 6 simultaneous measuring channels

Balancing and overall machine condition all in one place with our SmartBalancing Mode

Live time waveform with synchronized FFT for spectrum analysis all while balancing

Graphic display of the 1 x filtered vibration in polar vector diagrams

Centralized machine set-ups and data storage

Simple transfer and documentation of measurement results

Optical laser reference pickup with up to 2 m measurement distance

Elevate your performance with the comprehensive balancing package

The basic scope of delivery contains everything you need for field balancing: the SmartBalancer 4 unit, 2 acceleration sensors, laser reference pickup with a magnetic stand, all required connection cables, the power supply unit/charger, and a USB-C connection cable. 6 channel upgrade and further advanced analysis functionalities are available as an option. This makes SmartBalancer 4 an indispensable instrument in your business – an untiring worker and analyst.

Operational convenience for enhanced ease of handling

All functions of the unit can be operated easily and intuitively by means of a robust touch screen, even by inexperienced users. The brilliant color display with its easily understandable graphics and the simple file structure is based on the commonly used WindowsTM platform. This makes SmartBalancer 4 an efficient and practical tool for minimizing unbalances during ongoing operations.

A high-performance entity with a plethora of talents

To facilitate a comprehensive assessment of the machine's condition during the balancing process, we have incorporated multiple analysis tools.

From the measurement, evaluation, and diagnosis of the machine's state (sum vibration and frequency analysis), to the assessment of roller bearings, or a bump test, all the way to the documentation and archiving of all results, SmartBalancer 4 proves itself as a highly intelligent assistant during machine commissioning, service, and maintenance.

Now introducing an enhanced analysis package

Machines can exhibit mechanical vibrations because of unbalances, alignment faults, and incipient damage. To ensure that no fault goes undiagnosed the SmartBalancer 4 Advanced Analysis package can be provided.

The Advanced Analysis package provides a detailed analysis of the machine, including custom FFT frequency analysis, bearing envelope spectrums, time waveform, and cross-phase measurements. These supplementary functions can be added at any time, enabling even more comprehensive field analysis.

Documentation and archiving made effortless

The SmartBalancer 4 stores all results in the machine file, including the machine description and user comments.

It provides the date and time, overall values, and both the initial and final frequenc spectrums to generate a PDF Balance Report.

You can easily take screenshots of additional measurements, and both the Balance Report and screenshots can be transferred to your PC using a USB-C cable. This allows you to process all results independently and send them via email if necessary.

Quality assurance for the SmartBalancer 4

The SmartBalancer provides extensive possibilities for field balancing and is a reliable companion – even in rough environments. Nevertheless, the SmartBalancer 4 is a high-precision measuring instrument, which is used for direct machine evaluation. In order to ensure that the recorded data is reliable and verifiable, it is important to have the measuring system of your SmartBalancer calibrated periodically and

traceable. Complying with standards, this becomes a necessity to comply with standards such as DIN EN ISO 9001.

Protect your product quality and competitiveness with an examination of your SmartBalancer 4 and prevent errors that shorten the life time of your machines.