This product is only available in countries outside the CE and UL certification area.

SmartBalancer ECO

Field Balancing at its core

The SmartBalancer ECO offers its customers a valuable on-site balancing service and is ideally suitable for commissioning, servicing and maintenance of machines and systems. The dynamic balancing performed on completely assembled equipment in Operating Condition also compensates for assembly tolerances. The procedure runs in three stages i.e. Measurement, Correction and Check Run.

Easy, fast, accurate, reliable

The SmartBalancer ECO is a cost-effective alternative to the SmartBalancer 4, which was specially designed for simple balancing tasks. This device is equipped with all the necessary functions to ensure accurate and efficient balancing during operation without compromising on quality and know-how. With its intuitive and user-friendly interface, the SmartBalancer ECO is easy to use and delivers reliable results every time. Whether you're a professional mechanic or a technician, the SmartBalancer ECO is the right choice for you.

Simplify your work processes with outstanding ease of use

The SmartBalancer ECO gives you comprehensive control and handling in one hand. All of the device's functions can be controlled easily and intuitively via the touchscreen display, even by inexperienced users. The clear color display with easy-to-understand pictograms and the clear file structure are based on the familiar Windows interface. This makes the SmartBalancer ECO an efficient and practical tool for real-time detection of imbalances during operation.

Advantages at a glance

- Tremendous value for money

- 2 Simultaneous Measuring Channels

- Easy operation with Touch Screen and user guidance

- Measurement of overalls and frequency analysis

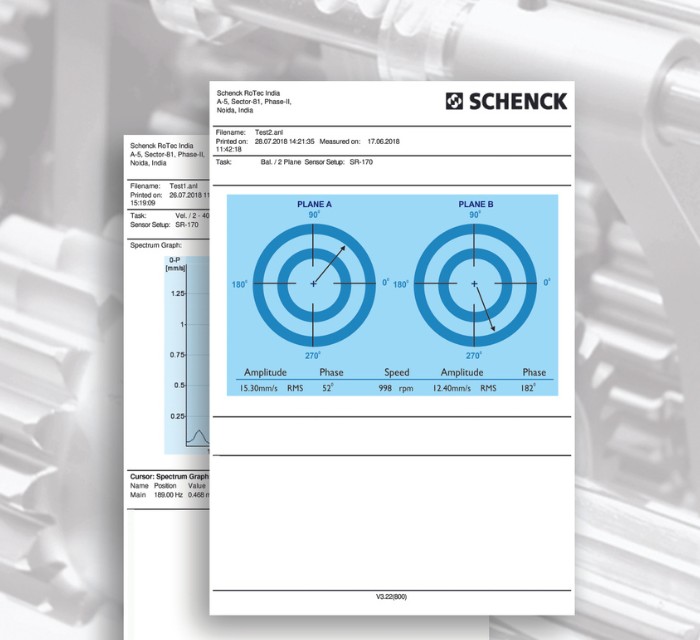

- Graphic display: Polar Plots and Spectra

- Complete package for field balancing in easy to carry soft case

- Optical reference pick-up with 1 m measurement distances

- Storage of data and influence coefficients

- Fast and easy installation

- PS Software for reporting and data archiving

Result of Fault Diagnostic Statics: Avoid Unbalance...

Alarming high rates of failure, over 50% are caused by unbalances in the torots resulting in mechanical vibrations, leading to premature bearing faulures, shaft deformation etc. Such unbalances can be easily diagnosed as well as corrected with the help of “SmartBalancer ECO”.

Data documentation

PC software EcoSmart - Intuitive to use WindowsTM based software to up and download stored data from SmartBalancer Eco, to archive data and to generate formated views and printouts of reports for documentation.

Overalls und FFT

For the identification of the cause of vibration, the SmartBalancer Eco offers high performance, 2 channel FFT frequency analysis which breaks down the vibration mixture occurring in the machine into their harmonic components and displays them clearly in the form of a spectrum to determine the causes of vibrations for subsequent correction.